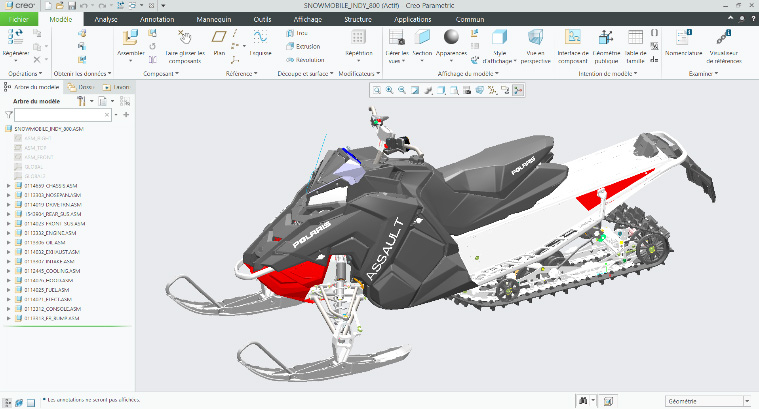

Creo is a 3D CAD solution designed to help you create better products faster; it accelerates product innovation and lets you recycle the best of your designs.

Creo supports you from the first phases of design through to the development of intelligent, connected products.

With Creo‘s powerful cloud-based augmented reality, you can collaborate with whoever you want, at any time, at any stage of the product development process.

With industrial CAD, think differently, be more productive and design smarter.

Optimizing time-to-market is a key element in standing out from the competition, and therefore in guaranteeing reliable and secure profits.

Demands are constantly increasing, and products are becoming ever more complex. Creo is the CAD system that takes all these demands into account, thanks to the continuous development of new features.

Creo 10

Creo 10 integrates new enhancements and features to help you innovate and design the products of the future faster.

With advanced modeling capabilities for simulation and collaboration with real-time augmented reality, Creo gives you a competitive advantage to meet today’s deadlines and capitalize on tomorrow’s opportunities.

Simplified

user

interface

Optimized

design for

3D printing

Simplified

implementation of

augmented reality

Proactive anticipation of

of the “Digital Twin” from

from the design office onwards

Realistic

rendering images

Simplified

user

interface

Optimized

design for

3D printing

Simplified

implementation of

augmented reality

Proactive anticipation of

of the “Digital Twin” from

from the design office onwards

Realistic

rendering images

With Creo 10, we’re pushing the limits of productivity even further. Hundreds of improvements let you work faster, with less effort. Here are just a few examples of what’s new in Creo 10:

• Workflow improvements for model tree restructuring: it is now possible to modify model tree lines for a better visual understanding of the structure.

• Pattern: pattern dimensions are more flexible to suit your use cases, with improved indexed references and new parameters indicating the number of actual members

• Interoperability to send 3D designs to printing and post-processing equipment

• Optimized, streamlined design: you can implement initiatives to design lighter products that perform as well as or better than previous versions.

• Mannequins: more realism when manipulating mannequins (placement in the assembly, angle measurement, and field-of-view analysis)

• Improved CAM: addition of 5-axis toolpaths, tool offset parameters, print support for all tool parameters and manual cycling

Creo +

Creo+ is the latest innovation in CAD solutions.

It combines the power and trusted features of Creo with new cloud-based services to enhance team collaboration, improve user productivity and streamline license management and administration.

No data

translation

Fully Creo

compatible

Identical

CAD features to Creo

Close integration

with Windchill

Evolution of SaaS

services in Atlas

No data

translation

Fully Creo

compatible

Identical

CAD features to Creo

Close integration

with Windchill

Evolution of SaaS

services in Atlas

Creo+‘s main components are:

• Cloud-based licensing

• Real-time synchronization and updates

• Management of groups, users and collaboration sessions

• Creo deployment automation

• License usage telemetry

Creo+‘s main benefits are:

• Reduce the time, effort and overhead involved in managing Creo licenses and deploying them to users, departments and regions.

• Real-time updates, automatically synchronized and accompanied by detailed feedback, so you always have the latest and best version of the design.

• Better visibility of overall Creo usage across the organization, groups and users

Creo Simulate

Simulation & Analysis

With Creo Simulation Live powered by ANSYS, you can get real-time advice on design decisions as you make them.

Creo Simulation Live runs in the background, providing feedback as you modify your part and/or assembly design.

Mechanical simulation with Creo Simulate offers you a host of features:

• Structural analysis

• Linear steady-state thermal analysis

• Material libraries

• Meshing

• Optimization

• Post-processing

With the Creo Flow Analysis extension, every engineer can carry out a CFD analysis.

As products become ever more complex, and lead times ever shorter, a CFD solution becomes indispensable, enabling you to ensure the correct flow of liquids and gases right from the start of the design process, through analysis.

With Creo FAE, you can reduce costly prototype testing and gain vital information about your products.

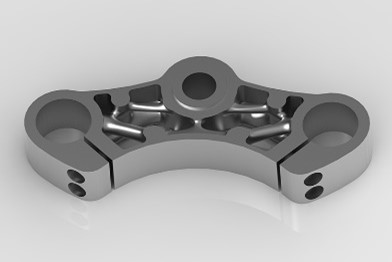

Generative Design

The design of your products is accelerated by generative design since Creo 7.

In the Creo Simulate environment, the tool generates design scenarios based on the requirements and constraints you have defined.

A cloud extension will even let you generate multiple designs at the same time, with the best design options automatically highlighted to help you make the best choices.

Generative design will make real-time simulation much more flexible, as it means you don’t have to leave the CAD environment. Generative design is perfectly suited to additive manufacturing.

Additive manufacturing

With Creo Simulate, you can design, optimize, validate models and then verify printing from a single environment.

Processing time is reduced to eliminate time-consuming and mistake-making tasks.

In particular, you can design your parts for polymer and metal additive manufacturing by connecting directly to the printer you want.

The file will contain optimized support and printer profile structures.

Currently, Creo Simulate enables you to cover 70% of the metal printers on the market.

Model-based definition

Creo 6 has set the standard for model-based definition.

In a model-based definition system, all product information resides in a fully detailed 3D model, accessible to everyone from engineers to package designers.

Improved processes make it easier than ever to create and publish the complete model-based definition.

Model-based definition systems offer many benefits:

• Increased productivity

• Reduced costs

• Consistency

• Elimination of errors due to human intervention

• Improved distribution of designs

• Improved understanding of the GD&T process